Views: 0 Author: Site Editor Publish Time: 2025-09-12 Origin: Site

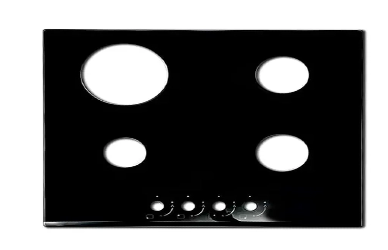

Gas Cookers Glass has become a popular choice in modern kitchens due to its sleek, stylish appearance, smooth, and easy-to-clean surface. Homeowners appreciate its ability to complement contemporary kitchen designs while offering a durable and reliable cooking platform. However, like any tempered glass product, it can be prone to cracking under certain conditions. Understanding the common causes of cracks is essential not only for maintaining the safety of your kitchen but also for extending the lifespan and performance of your cooktop. By knowing how and why cracks occur, users can take effective measures to prevent damage and ensure their Gas Cookers Glass remains fully functional and visually appealing for many years.

One of the most frequent causes of Gas Cookers Glass cracking is thermal shock. This occurs when the glass experiences sudden changes in temperature—for example, pouring cold water onto a hot cooktop or placing a very hot pan on a chilled surface. Tempered glass can withstand high heat, but abrupt temperature swings create stress that may lead to cracks or even shattering. Frequent exposure to such temperature changes over time increases the likelihood of damage.

Heavy pots, pans, or dropped kitchen utensils can also damage Gas Cookers Glass. While tempered glass is designed to be strong, it is not immune to sharp impacts or excessive force. Even small chips caused by dropping items can develop into larger cracks over time if not addressed promptly, potentially compromising the safety and functionality of your cooktop.

Sometimes, cracks appear due to imperfections in the tempered glass itself. Issues during the manufacturing or tempering process—such as uneven heating, internal stress, or minor flaws—can weaken the glass. Choosing high-quality, certified Gas Cookers Glass from reputable manufacturers helps minimize this risk and ensures long-term durability.

Incorrect installation is another common factor. If the cooktop is placed on an uneven surface or is poorly aligned, stress points may form, making the glass more susceptible to cracking. Ensuring proper installation according to the manufacturer’s guidelines is essential for both safety and longevity, as even minor misalignments can lead to significant problems over time.

One of the most obvious indicators that Gas Cookers Glass is under stress is the appearance of hairline cracks or small chips on the surface. Even minor damage can compromise the structural integrity of the glass over time, gradually increasing the risk of larger cracks or sudden shattering. Regular inspection of your cooktop’s surface can help detect these issues early, allowing you to take preventive measures before the damage worsens and potentially causes safety hazards in your kitchen.

A warped, uneven, or slightly bowed surface can indicate that the Gas Cookers Glass is experiencing internal stress. Pressure points, particularly around the edges or corners, may develop due to improper installation, uneven support, or continuous thermal cycling during cooking. These stressed areas are more susceptible to cracking if left unaddressed, so noticing and correcting uneven surfaces promptly can prevent further damage and extend the lifespan of your cooktop.

Stressed Gas Cookers Glass can sometimes produce unusual sounds, such as clicking, popping, or faint cracking noises, when heated or cooled rapidly. These sounds are caused by the expansion and contraction of the tempered glass and serve as warning signs that the material is under tension. Paying close attention to these auditory cues can help prevent unexpected breakage, ensure safe use, and allow you to take action before the glass suffers more serious damage.

Proper handling is essential to protect Gas Cookers Glass from cracking and ensure safe, long-lasting use. Avoid sudden temperature changes, such as placing cold cookware on a hot surface or pouring cold liquids onto a heated cooktop, as this can cause thermal shock. Additionally, do not drop heavy pots, pans, or utensils on the glass surface, as even tempered glass can be damaged by strong impacts. Being mindful during cooking and handling utensils carefully can significantly reduce the risk of cracks.

Ensuring correct installation can greatly reduce the risk of cracks and improve the performance of your Gas Cookers Glass. The cooktop should be mounted on a level and stable surface with adequate support underneath to prevent stress points. Following the manufacturer’s guidelines for spacing, alignment, and securing the cooktop helps distribute pressure evenly across the glass, preventing areas of concentrated stress that could lead to breakage over time. Professional installation is highly recommended for optimal safety.

Routine inspection and careful cleaning are crucial for maintaining the integrity and appearance of Gas Cookers Glass. Check for minor cracks, chips, or scratches regularly, and address any issues promptly before they worsen. Use only the recommended cleaning methods and avoid abrasive sponges or harsh chemicals that could weaken or scratch the surface. Regular maintenance not only extends the lifespan of the cooktop but also ensures it continues to look sleek and perform safely over years of daily use.

Selecting certified tempered glass from reputable manufacturers is essential for ensuring the quality and safety of your Gas Cookers Glass. High-quality materials are less prone to manufacturing defects, better withstand heat, impact, and everyday wear, and provide long-term durability. Investing in premium, certified glass gives peace of mind and helps maintain a stylish and reliable cooking environment, reducing the likelihood of unexpected cracks or damage.

If your Gas Cookers Glass develops large cracks, deep chips, or fractures that affect a significant portion of the cooktop, it is crucial to replace it immediately. Such damage compromises the structural integrity of the glass, making it highly susceptible to shattering during normal use. Continuing to cook on a damaged glass surface poses a serious safety hazard, as sudden breakage could cause injuries, spills, or damage to cookware. Prompt replacement ensures both safety and the continued functionality of your kitchen.

Even if no obvious cracks are visible, there are warning signs that indicate your Gas Cookers Glass may be under stress and at risk of failing. Hairline fractures, warping, or unusual clicking or popping noises during heating and cooling are all indicators of internal tension in the glass. Detecting these signs early and replacing the cooktop proactively can prevent accidents, maintain cooking performance, and avoid costly emergency repairs.

When it becomes necessary to replace a damaged Gas Cookers Glass, always opt for original or certified replacement parts from reputable manufacturers or trusted suppliers. Using low-quality or incompatible glass can compromise safety standards, reduce durability, and increase the likelihood of future cracking. High-quality replacements not only restore the structural integrity of your cooktop but also ensure that it performs reliably and maintains its sleek appearance. Investing in certified parts is essential for long-term safety, functionality, and peace of mind.

Gas Cookers Glass is a popular choice for modern kitchens due to its sleek appearance, smooth surface, and ease of cleaning. However, it can be prone to cracking if not handled properly. Common causes include thermal shock, impact damage, manufacturing defects, and improper installation. To extend the life of your cooktop, it is essential to follow proper usage practices, ensure correct installation, conduct regular maintenance, and choose high-quality materials. By taking these preventive measures, homeowners can enjoy the style, functionality, and durability of Gas Cookers Glass safely for many years, while minimizing repair costs and maintaining a visually appealing kitchen environment.